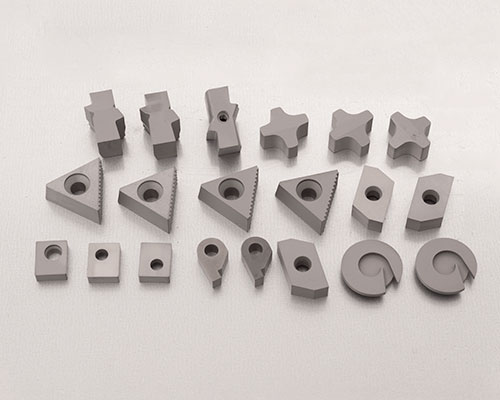

Types of hard alloys

Tungsten carbide/cobalt (WC/Co) : Tungsten carbide/WC/Co) : The first sintered hard alloy for commercial use was made by bonding tungsten carbide high Angle particles to cobalt metal. Bonded to cobalt metal. For maximum hardness obtained from packing density, tungsten carbide fine particles should be as small as possible, Z less than 1μm 0.00004 in. 1μm (in.), Z less than 1μm (0.00004 in.) and quite small for special purposes. With the decrease of cobalt content its hardness and wear resistance increase, to be quite small. With the decrease of cobalt content, its hardness and wear resistance increase. It is only necessary to ensure that there is a low content of Z cobalt in sintering (2% is enough), although the actual low content of Z is 3%. In short, 3%) content is 3%) will do. In general, as the amount of fine carbide or cobalt or both increases, harder or softer grades are obtained. With the increase of, you gain a harder or softer rank. Many of the tungsten carbide/cobalt components are modified by a small but very important additive into many tungsten carbide/rows -- 0.5 to about 3% tantalum -- from about 3% tantalum, row adjusted -- from 0.5 to about 3% tantalum, niobium, chromium, vanadium, titanium, hafnium, or other carbides. The basic use of these additives is generally to inhibit the growth of fine particles, other carbides. The basic use of these additives is generally to inhibit fine grain growth and thus maintain a consistent fine structure. Thus a consistent fine structure can be maintained. Tungsten-titanium carbide/tungsten-titanium carbide/Cobalt (WC/TiC/Co) : WC/TiC/Co) : These percentiles are used as a tool to cut steel and other iron-based alloys. The TiC component is designed to resist the high temperature diffusional impact caused by chemical decomposition and pitting. Tungsten carbide diffuses to the surface of the blade, sexual impact. Tungsten carbide diffuses to the surface of the blade, but titanium carbide is extremely resistant to this diffusion. TiC solid solution or solid solution crystal "WC" remains resistant to the form of solid solution or "extremely resistant. The solid solution or "solid solution crystal" WC in TiC retains its pitting resistance to a great extent. Pitting nature to a large extent. Unfortunately, titanium carbide and TiC based solid solutions are very brittle and not as durable as tungsten carbide. Therefore, the TiC content should be kept as low as possible. The TiC content is kept at Z low level. Therefore, the TiC content should be kept as low as possible. In the limiting formulation, the carbide is tungsten-free and completely TiC based, but generally the TiC content should not exceed 18% and if it exceeds this, the TiC content should not exceed 18%. Above, but generally, the TiC content cannot exceed 18%. If the carbide exceeds this value, it becomes too brittle and very difficult to braze. Carbide becomes too brittle and very difficult to braze. The composition of WC/TiC/Co has two distinct carbide phases. In general, the composition of WC/TiC/Co has two distinct carbide phases, almost pure WC Angle crystals and rounded TiC/Co mixed crystals. WC Angle crystals and rounded almost pure WC Angle crystals and rounded TiC/Co mixed crystals. In the developing manufacturing industry, although WC/TiC/Co hard metal is very widely used, WC/TiC/Co hard metal is very widely used in the manufacturing industry, it is forbidden to use in some important considerations. They are replaced in many applications by the WC/TiC/Ta(Nb)C/C9 series with higher strength and pitting resistance. TiC and TiN were replaced by WC/TiC/Ta(Nb)C/C9 series, which had the advantage of pitting resistance. TiC, TiN, and other coatings on hard substrates have also reduced the attraction of high TiC components to high speed processed steels and ferroalloys. The attraction of TiC components to high TiC components.

Tungsten carbide Tungsten-titanium-tantalum (-niobium)/cobalt: The tungsten-titanium-tantalum (-niobium) grade is probably the most common hard metal grade of Z in addition to carbide coating. Mainly used in cutting steel, can be Z common hard metal grade. Mainly used in cutting steel, they combine and improve the long established WC/TiC/Co WC/TiC/Co composition. They combine and improve the long established WC/TiC/Co composition of most of the characteristics. These carbides can be directly associated with carbon majority properties. These carbides can be directly comparable to carbon-nitrogen compounds and silicon carbide ceramics, silicon carbide ceramics comparable, and this grade of Z good hard alloy can complete the high-speed cutting of all types of steel, can complete the high-speed cutting of all types of steel, including austenitic stainless steel series. Body stainless steel series. These tools also work well in ductile cast iron and nickel-based ultra-heat resistant alloys, and also in hot alloy operations during these cutting processes, where large amounts of heat can be generated at very high pressure at the cutting edge. However, a large amount of heat can be generated at the cutting edge at a very high pressure. However, they do not have the wear resistance of fine-grained pure tungsten carbide grade, they do not have the wear resistance of fine-grained pure tungsten carbide grade, or the good resistance of the rubber grade, the good resistance of the rubber grade pit, and the properties of titanium carbide foundation ceramics. The property of

Titanium carbide/Titanium carbide/molybdenum/nickel (TiC/Mo/Ni) : TiC/Mo/Ni) :

The extreme pressed hardness and pitting resistance of titanium carbide combined with the cheapness and availability of its main raw material, titanium dioxide (TiO2), provides a strong incentive to use quality based on this single carbide. This carbide alone, though, provides a strong incentive to use quality. Developed in the early history of hard metals, these carbides were rarely used until the advent of jigs because they were difficult to perform satisfactory brazing. What's more, the brittleness of such carbides is notorious for its application. What's more, the carbide is notoriously brittle and can only be used in fine cutting conditions with minimal vibration. It can be used in fine cutting conditions with minimal vibration. ? The very high hardness values recorded for the pressed titanium carbide do not simultaneously have the same level of wear resistance, the corresponding level of wear resistance, it is believed that the apparent lack of hardness of tungsten carbide in this respect more than titanium carbide performance. In addition, the performance of carbon nitrogen compounds, tungsten in this respect is more than titanium carbide. In addition, nitrogen compounds, advanced tantalum-containing polycarbides, and coated variants generally provide better overall cutting performance. For better overall cutting performance.