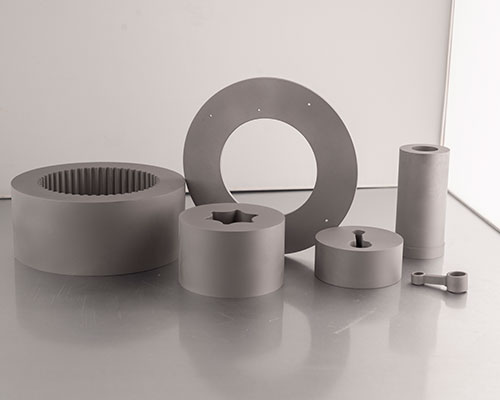

Powder metallurgy material special, aviation field potential!

At present, the weight of commercial aircraft engines generally ranges from 2,000kg to 8,500kg, of which powder metallurgy materials account for 85% to 95% of the weight of the engine. Due to its unique combination of attributes, including high strength, high toughness, high degradation resistance and good surface stability in the process of thermal engine cycle and in the process of engine operation encountered severe oxidation and corrosive environment, metal has always occupied a dominant position.

Powder metallurgy material special, aircraft engine aspect plays a huge role!

The thermodynamic cycle determines the temperature and pressure of gases, so every part of the engine has to find the right material -- from the front fan all the way to the compressor, burner and turbine.

For fans, low density materials with high toughness are preferred as blades. Titanium alloy and polymer matrix composites as well as some aluminum composites are favored and have higher productivity. Air flow through the compressor after the temperature rise to 700 incorrect jee, this part includes titanium alloy blade and disc.

In the burner part, high temperature nickel base and cobalt base alloys (with moderate strength and easy processing) have become the main materials of the structure. After combustion, the gas temperature ranges from 1400℃ to 1500℃. As it enters the high-pressure turbine, the rotating turbine blades are subjected to the intense stress and temperature combination of the engine.

Turbine blade is a special aerodynamic thermal component of Z, whose thin-walled and multi-layer structure drives a complex internal cooling system. At present, turbine blades are mainly made by coating a single crystal nickel-based ultra-high temperature resistant alloy substrate with an intermetallic bond coating, followed by a porous, low conductivity yttrium oxide stabilized zirconia top coat as a thermal barrier.

The blades are attached to a turbine disc made of a polycrystalline form of a nickel-based alloy. As one of the safest and most critical components in an engine, the disc is often formed from powder metallurgy and superplastic forging to maximize strength and fatigue resistance.

By extracting hot gas from the turbine, the gas temperature again drops to a moderate level below 800℃. The rotating and static components in the rear section of the turbine are mainly composed of nickel-based superalloys. For an engine shaft, it must have very high strength and fatigue resistance, and is usually made of high-strength steel or nickel-based superalloys.