Development of metal powder injection molding technology

Metal injection molding is a kind of high technology which combines traditional powder metallurgy technology with plastic injection molding technology. Metal injection molding started in the late 1970s. In the past, due to the lack of suitable powder or high price of raw materials, imperfect knowledge platform, immature technology, time needed for people to understand and market acceptance, too long production cycle (including mold manufacturing), insufficient investment, its development and application were slow. In order to solve the difficulties of metal injection molding technology, then Japan, Germany and other countries have joined in the development and research of metal injection molding. Powder metallurgy die

The basic and application research of metal injection molding has been carried out by many institutions, such as the National Engineering Center of Powder Metallurgy, Central South University, Beijing Iron and Steel Research Institute, etc., and remarkable results have been achieved. With the continuous deepening of scientific research on metal injection molding and the development of new binders, powder technology and degreasing technology, industrialization has been realized in the early 1990s. After more than 20 years of efforts, metal injection molding has become a promising new near-net forming technology in the field of powder metallurgy, known as? The international most popular metal parts forming technology.

Not only so the basic process of metal injection molding, the first is to select the metal injection molding to meet the requirements of metal powder and binder, and then at a certain temperature using the appropriate method to mix the powder and binder into uniform injection molding feed, after granulation in the injection molding machine injection molding, the forming billet obtained after degreasing treatment sintering dense into the final product.

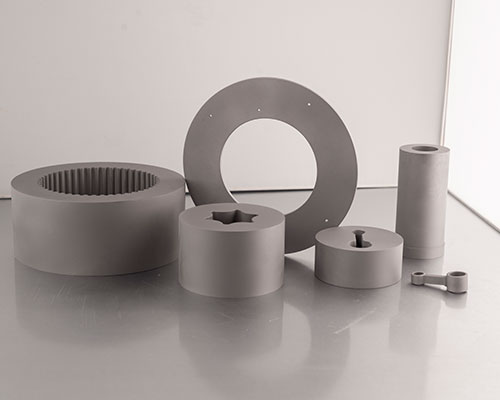

Metal injection molding process includes product design, mold design, quality testing, mixing, injection, degreasing, secondary processing and other eight important links metal injection molding combines the advantages of powder metallurgy and plastic injection molding two technologies, breaking through the traditional metal powder molding process in the shape of the product.

Metal injection molding uses the technical characteristics of metal powder to produce dense mechanical parts with good mechanical properties and surface quality by sintering. The plastic injection molding technology is used to produce complex shaped parts in large quantities and with high efficiency. The advantages of metal injection molding technology are mainly shown in the following aspects :1, can produce very complex shape parts; 2, sintering densification degree is high, performance can be compared with forging materials; 3, can maximize the production of the final shape of the parts without subsequent machining or only with a minimum of machining; 4, high material utilization rate, suitable for mass production; 5, equipment investment is small, and can automatically control the whole process, high production efficiency.